CAPABILITIES

We offer a vertically integrated network of capabilities starting from raw material production,

finished good converting and packaging, ending with sterilization.

SCROLL

Raw Materials

Non-woven fabrics such as SMS, SPP, Meltblown, and film are all

produced in house and prepared for conversion into finished goods.

1

SPP

Newly installed state of the art SSS line dedicated

for spunbond production

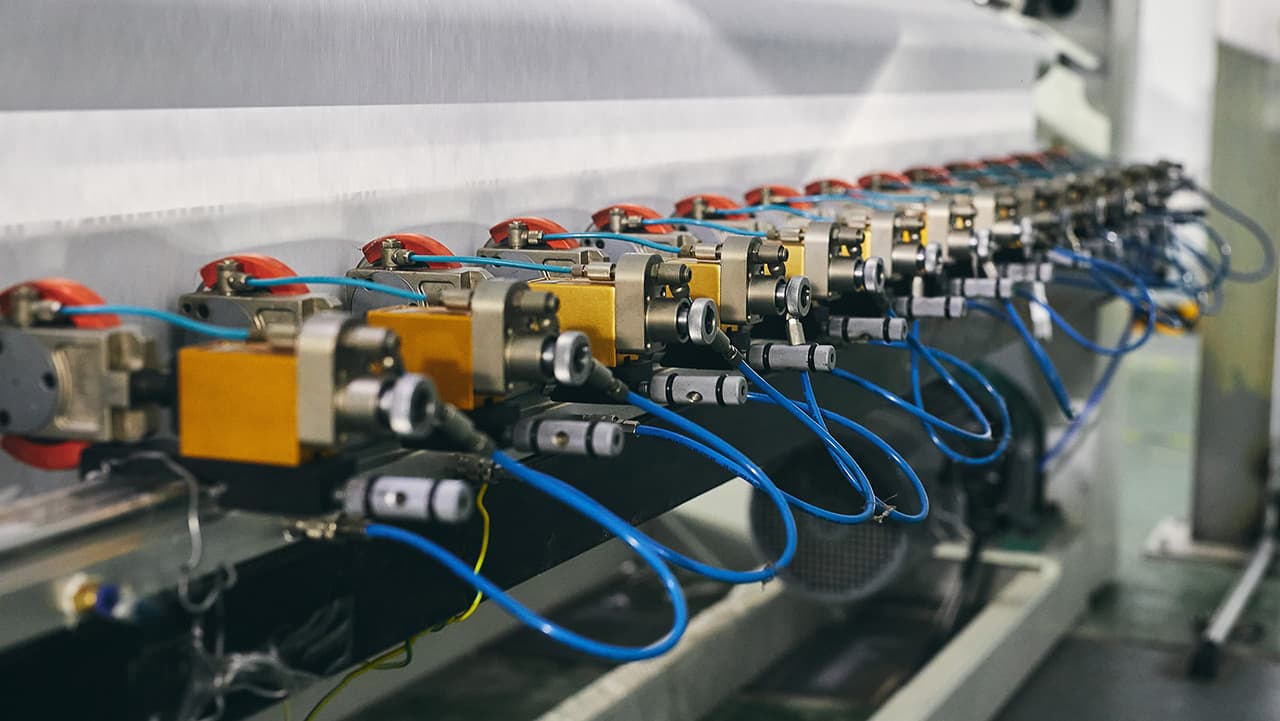

MELTBLOWN

Meltblown lines utilized for production of

filtration membranes and materials for a variety of different filtration applications and

industries

SMS

SMS lines provide materials that meet both medical

and hygiene industry needs

AS/AR

Specialty finishing lines coat and treat our non

woven materials to help ensure the safety and protection of our end users

Cast Film

Extrusion lines provide film and laminated materials

that are high in strength and fluid resistant

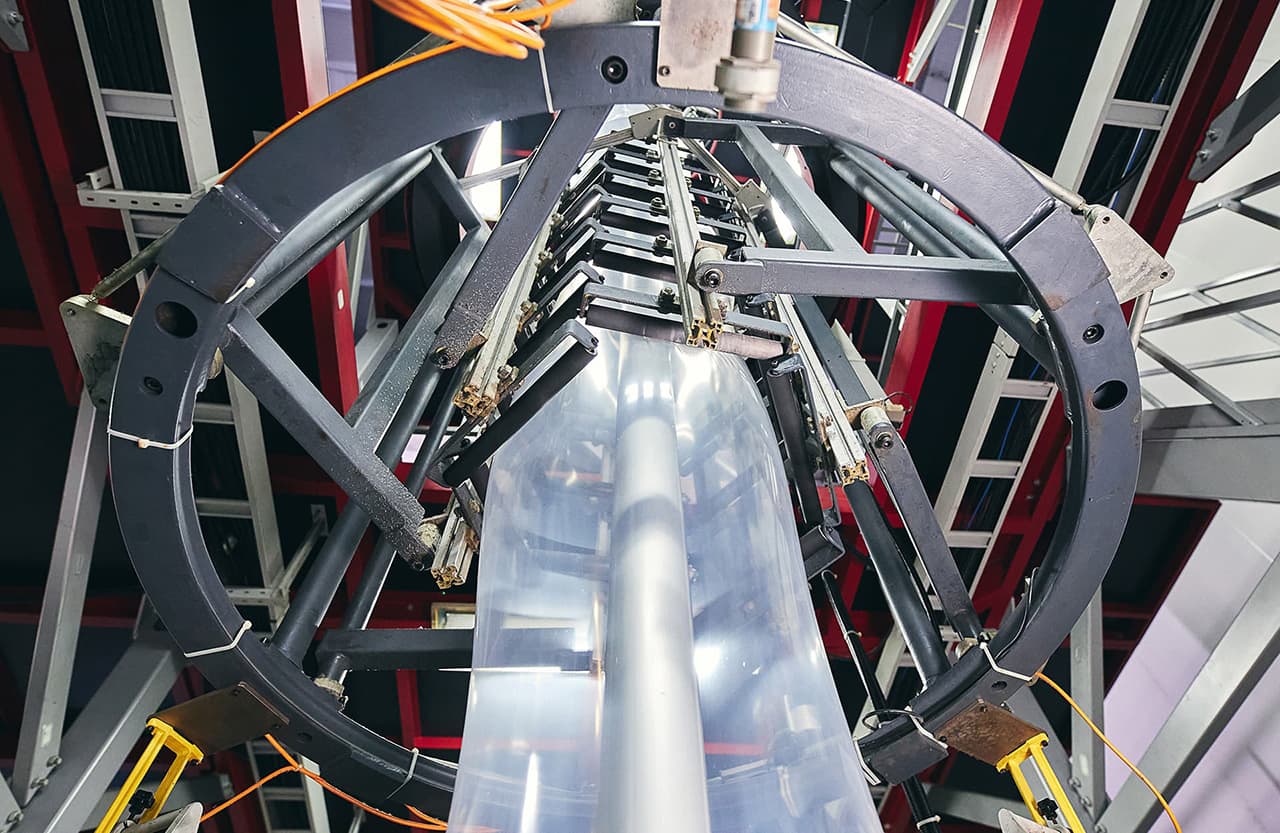

BlownFilm

Both single and tri layer blown film machines are

used to manufacture a wide variety of films

Hot-melt laminate

Laminates produced via hot-melt adhesives

CONVERTING

Front line workers and automated machinery convert fabrics and

accessories into finished goods.

2

Cutting and Sewing

Decades of experience in producing surgical and

infection control apparel

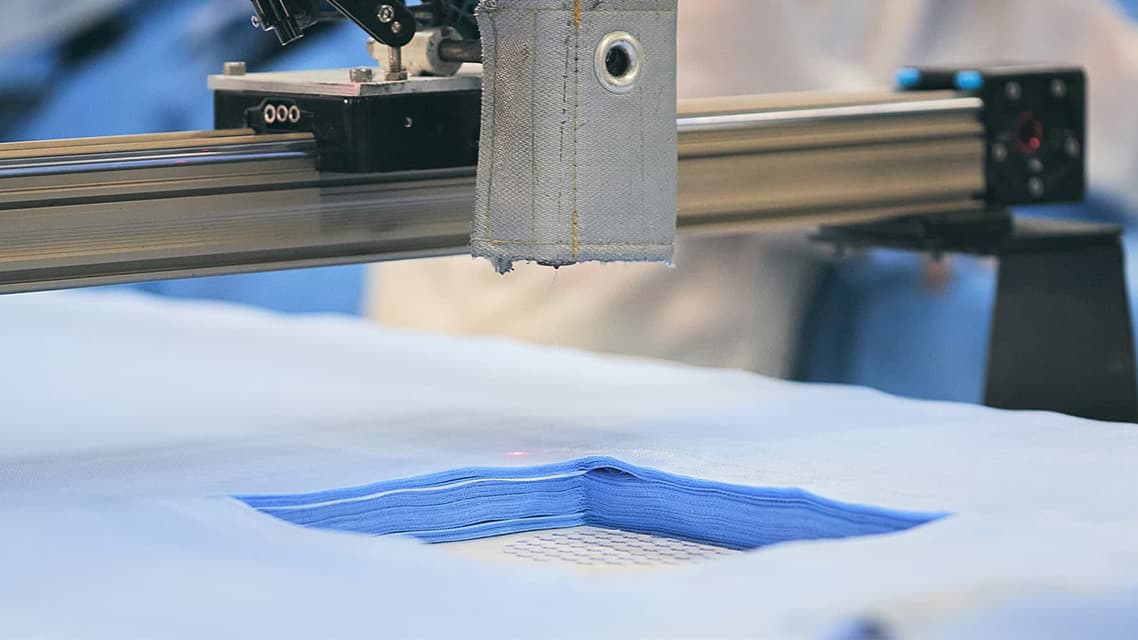

Surgical drapes

Advanced fully auto and semi-automatic

production lines are utilized for a variety of surgical drape production

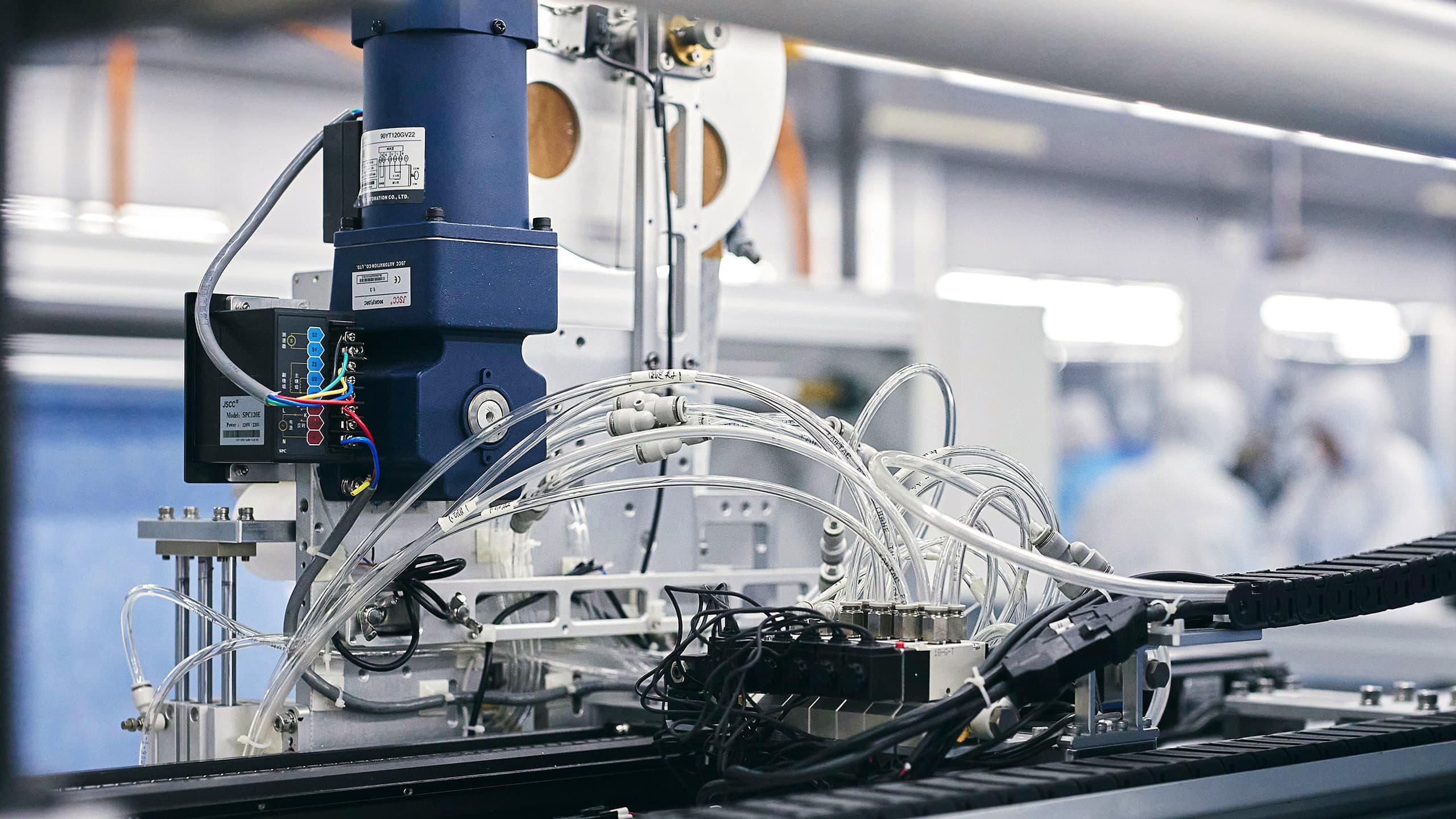

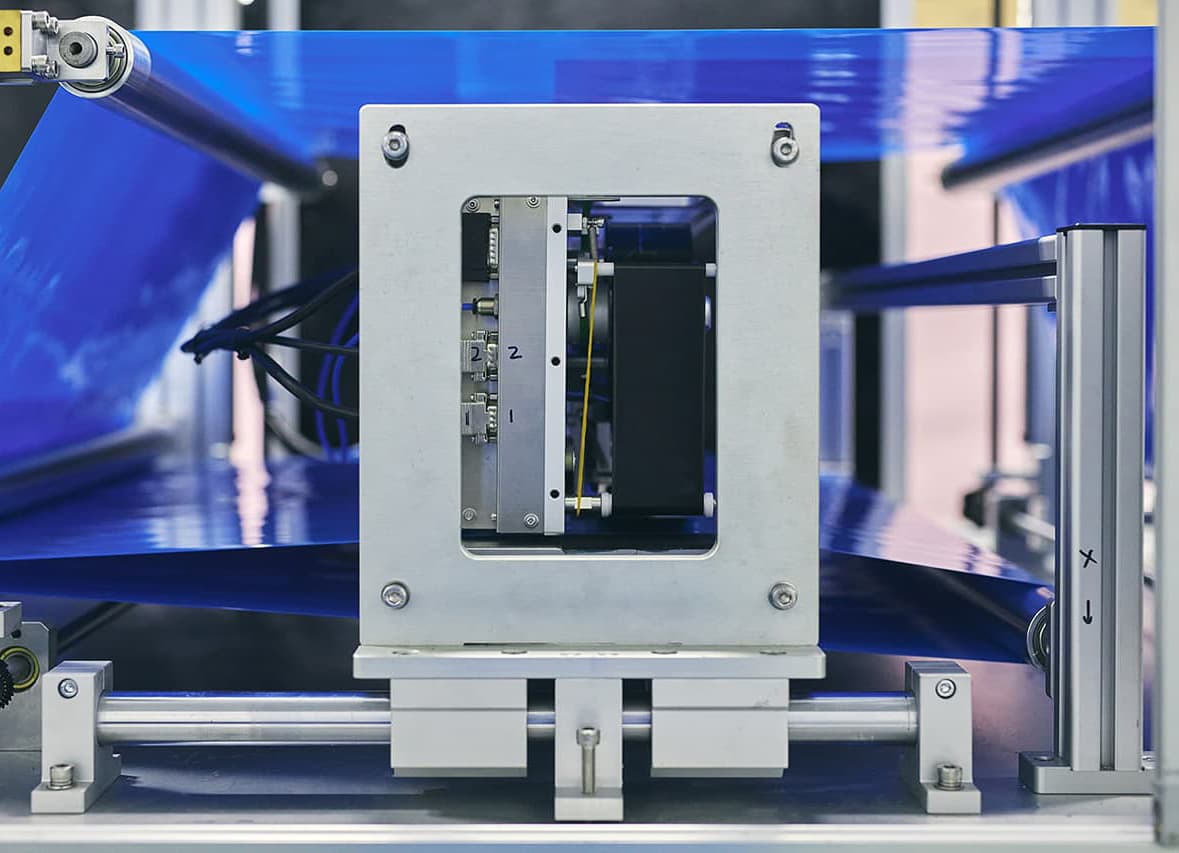

In house Designed Automation Machinery

Dedicated team of engineers to research and develop

new equipment and machines to increase production efficiency

Sterilization

ETO chambers sterilize the goods and then the sterilized products are

prepped for shipment.

3

Upgraded EO sterilizers and in-house lab provide sterile

goods while ensuring the surrounding environment remains unharmed

CONTACT US

Human Resource Team

Sales Team